We provide warehouse service, store various kind of products which more than 5,000 square meters at Bangplee Industrial Area.

We have a complete Warehouse Management System(WMS) that include product management and distribution.

TYPE OF WAREHOUSES

Warehouse is a place used to place, deposit and store goods such as finished goods that related to agriculture, industry and commerce, raw materials or semi-finished goods. There will be a system to manage inventory and clearly categorize.

Warehouses are preferred by manufacturers, importers, exporters, retail and logistics businesses. Mostly warehouse designs are single-storey buildings, there is a wide open area. In some places there may be a temperature control system, flood protection system or other systems to prevent the goods from deterioration or damage, and often designed a slope for conveying, loading and unloading goods into the car.

At present, there are many warehouses for rent. Most of the locations are in the suburbs and out of the city in order to have enough space for storing goods. Some warehouses are located next to the port, airport, train station or industrial estate to make moving or transporting goods more convenient and faster. Most warehouses tend to store pallets in layers to save space and use a forklift to lift or move.

The importance of warehouse

Warehousing is a very important element in logistics. The main function of the warehouse is used to store raw materials, semi-finished goods, finished goods, parts and goods in the process of production. Warehouse also include receiving goods, storing, collecting, changing, packing and sending products, as well as a point of receiving returned goods. Some warehouses are also used as locations for labeling, wrap the product or used for sorting goods before distributing to other sectors, so warehouses are important to help keep products in perfect condition and ready to deliver to recipients such as customers, organizations, individuals, sectors or related agencies. The warehouse is the part that supports the production, distribution and transportation.

Type of warehouse

Warehouses are classified according to business type, which are divided into two types: public warehouses and private warehouses.

1. Public warehouse

This type of warehouse is managed by the government which is a warehouse that provides storage services by collecting rent, allocate space to customers from many company and can rent space for storage of products as needed. It also supports small and medium-sized businesses that do not have enough space for storage. This type of warehousing is cost-saving for business people because they do not need to do their own warehousing.

2. Private warehouse

This type of warehouse is the general warehouse of each company which has created a personal space to store goods and can store products as needed. To build this type of warehouse need to use high capital but it’s worth it in the long run. It is also easy to manage inventory and can know the status of the warehouse at all times. Private warehouses may be directly adjacent to the parts that produce goods in the manufacturer’s factory.

Warehouses classified by the nature of work or the nature of the goods stored.

This type of warehouse is used for storing goods in the form of raw materials or finished goods. And emphasis on preserving product condition and preventing product loss. It is divided into 2 types, namely distribution centers and product collection and distribution centers.

1. Distribution center (DC)

It is a warehouse that connects manufacturers and retailers, provides storage and transportation services for customers. Most of the distribution centers are outsourced or Third party Logistics Providers (3PL) who receive goods from each manufacturer and store them in the warehouse, carry out control of the distribution and delivery of goods on behalf of the product owner or manufacturer. This can reduce the cost of transporting of the manufacturer to the retailer or the customer because the manufacturer can only transport to one distribution center and distribute products to many places as needed without the need for warehouses. It has an advantage in terms of price and speed of service.

2. Collection and distribution center (Cross dock)

It is a warehouse for receiving and delivering goods at the same time. Specially designed for transporting cargo from vehicle to vehicle. Cross dock will carry and sort cargo and will act as a transshipment station between modes of transport to deliver to each customer. Mostly will be retailers with a wide variety of sub-products.

The characteristics of the collection and distribution center (Cross dock) will have 2 sides, one side used for receiving goods and the other side is used for shipping. Usually the goods are collected and delivered within 24 hours.

The collection and distribution centers are scattered by regions and provinces which is the center of transportation. It can connect various forms of transport, whether it is rail, car, sea and air transport.

Warehouses that are classified according to the nature of the goods are divided into 4 categories, namely general warehouses, fresh goods warehouse, dangerous warehouse and special warehouse.

1. General warehouse

It is a warehouse that stores goods that do not require special care, such as consumer goods, general appliances.

2. Fresh goods warehouse

It is a warehouse used to store fresh items such as food, vegetables, fruits and beverages. It is often a product that requires special care by keeping the temperature at the right level to maintain the freshness of the product.

3. Dangerous warehouse

It is a warehouse where store dangerous goods such as toxins, chemicals, fuels and explosives. This type of warehouse has to be classified as hazardous material and stored properly. Therefore, this type of warehouse must have a supervisor in the pollution treatment system which must be licensed by the Department of Industrial Works.

4. Special warehouse

It is a warehouse that stores small items. To store high-value products, therefore, the temperature and humidity must be properly controlled. In order to prolong the quality of products such as pharmaceutical products including some chemicals.

Warehouses are classified according to the nature of warehouses, which are divided into two types: closed warehouses and open warehouses.

closed warehouse

1.A closed warehouse is an indoor warehouse that resembles a building. There are walls on all four sides to protect the product from variables that may cause damage to the product, such as climate, pests, etc. This warehouse is suitable for entrepreneurs of all kinds of products related to the consumer industry.

open warehouse

2.An open warehouse is an outdoor warehouse that contains only poles, fences, or other territorial markers, without buildings. It is suitable for goods that will not deteriorate from the effects of climate and can be stored outdoors, such as cars, motorcycles, etc.

Warehouses are classified according to their location, which are divided into 2 types: central warehouse and regional warehouse.

1.central warehouse

The central warehouse is the one closest to the production center to reduce handling and transportation costs. Mostly central warehouses are located in industrial estates such as warehouses for rent, Amata located in Amata City Industrial Estate, etc.

2.provincial warehouse

Provincial warehouses are those that are closest to the center of consumption. For example, if you are a wholesaler and distributor for businesses throughout the North. Operators may consider renting warehouses located in Lamphun, Lampang or Chiang Mai, etc.

Types of warehouses can be classified according to physical characteristics as follows

1. A warehouse that is closed with walls, ceilings and doors, such as general warehouses. Somewhere have temperature control or have a chiller installed (Frozen Warehouse).

2. A warehouse with only a roof but no walls, used to store goods that are not damaged by the weather. It is usually a large and heavy item, which the chance of damage or loss is difficult.

3. Outdoor warehouse – The floor must be concrete, have a raised floor and a flood protection system, no roof or buildings. Without that feature, it’s not an outdoor warehouse, but be a general warehouse. An outdoor warehouse may include a yard used to stack containers such as an ICD, port or airport. Outdoor warehouse Used to store large goods, bulk goods, field crops or minerals.

4. A warehouse that is a tank or other construction where goods are imported or removed by means of suction through pipes such as oil storage, chemical storage, silo to store animal feed and various agricultural products.

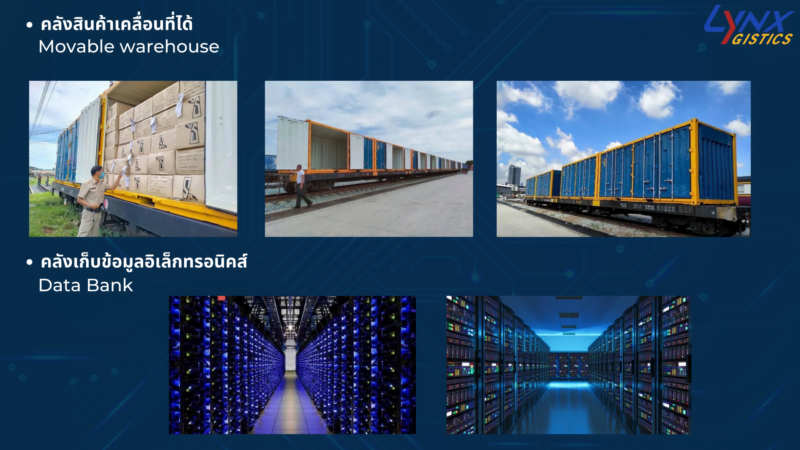

5. Movable warehouse, including the deck of the cargo ship, aircraft, train cargo bogies or containers that used to transport goods used as a storage facility for consignment.

6. Electronic data storage (Data Bank) such as server used to store data which is currently considered a type of product which can be delivered to those who need it by download via network such as Web site etc.

Bonded Warehouse

This type of warehouse is for imported goods that need to be inspected by customs. Therefore, this type of warehouse is directly managed by the government for paying taxes on the imported goods before the company can carry out transportation to the next location. As a result, most bonded warehouses are usually located at ports or airports waiting for excise tax and customs collection to be completed first.

Inventory management

Inventory management, including a list of finished goods, goods during production, raw materials, consumables and assets. All of this must be movable nature that known as movable property, which is considered a valuable item that may be owned and negotiable. The product must be paired with the warehouse and is the most important part of the Supply Chain Management system (SCM) because the main mission of the SCM is to move and deliver the goods, and must be physical goods. Electronics product has to move through Media, whether Disc, server or electronic media for services that will be included with the product. The main objective of logistics management is to create customer satisfaction, called Efficient Consumers Response or ECR, with operational costs at the Economy Scale level. If we set the level of the inventory at excessive level, it may look safe, but it will also result in high working capital requirements. Therefore, there must be appropriate inventory management.